Several of these projects are a direct result of the new house bought this Spring by my eldest. We did a gut-job on a bedroom that had some ungodly stucco-like material globbed on the walls. Lots of new flooring in the entire basement and some bedrooms, and a few woodworking projects.

First up is a sideboard to go with the dining set I made a few years ago for him. This provides some much needed storage in their expanded environs.

|

| Painted and Stained Sideboard to match existing dining room set |

A fence to ensure the Yorkshire monster does not make an exscape from the compound...

|

| Nice wooden fence to keep Rudy in and the Rakins out! |

In an unfinished room that was to become the gym, we decided to enclose the power panel, to reduce the ugliness...

Simple plywood sides and laminated pine-panel doors make short work of this enclosure.

He also needed a place to organize his sport equipment, so I made a stand to fit in the corner which looks like a pallet...

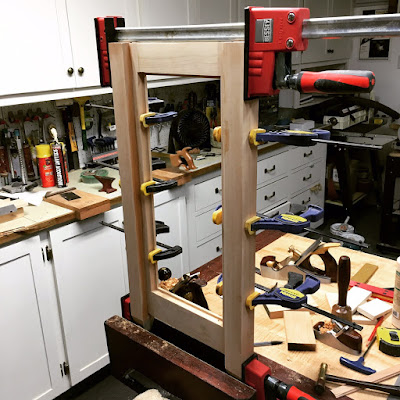

The kids are not the only ones requesting "off-the-wall projects" SWMBO wanted to recyle the windows we kept when we replaced the front door. I decided to install the sidelight piece in an interior wall to cast some light in the back hallway. This turned out quite nice.

She also had a request to make some props for the front step to hold some harvesty type decorations. I have been storing some western red cedar in the shed for years, so lugged it down, ripped it up and turned out a couple of sets of these. One set is going to one of the sons (of course) and the other will grace our entrance for the fall season.

She also had a request to make some props for the front step to hold some harvesty type decorations. I have been storing some western red cedar in the shed for years, so lugged it down, ripped it up and turned out a couple of sets of these. One set is going to one of the sons (of course) and the other will grace our entrance for the fall season.

|

| ...and after. |

Simple plywood sides and laminated pine-panel doors make short work of this enclosure.

He also needed a place to organize his sport equipment, so I made a stand to fit in the corner which looks like a pallet...

And now for something completely different...

One Saturday afternoon in August I was perusing the woodworking blogs and saw a project where a guy used a Kutzall grinding wheel to rough out a bowl from a chunk of wood. I use this setup for grinding seats out for chairs and rockers, so I said "I can do that". |

| A window to nowhere in particular |

She also had a request to make some props for the front step to hold some harvesty type decorations. I have been storing some western red cedar in the shed for years, so lugged it down, ripped it up and turned out a couple of sets of these. One set is going to one of the sons (of course) and the other will grace our entrance for the fall season.

She also had a request to make some props for the front step to hold some harvesty type decorations. I have been storing some western red cedar in the shed for years, so lugged it down, ripped it up and turned out a couple of sets of these. One set is going to one of the sons (of course) and the other will grace our entrance for the fall season.

It has been a busy, varied and glorious summer, time to move the operation inside. I have several exciting projects planned for this fall, so stay tuned.

RDW