Like many of my woodworking compatriots I have adopted the use of Instagram to share the happenings in my shop. As a result my blog posts have diminished. I am determined to keep this running log of major activities, so this will serve as a an update on what I have been up to.

Like many of my woodworking compatriots I have adopted the use of Instagram to share the happenings in my shop. As a result my blog posts have diminished. I am determined to keep this running log of major activities, so this will serve as a an update on what I have been up to.Click on any of the pictures to see them a bit bigger.

The end of 2015 brought to a closure my foray into the luthierie, I sold all my guitar making tools, jigs, plans, hardware, and bits to a friend who is starting up his own guitar shop in Dartmouth; I hope this gives him the head start he needs. He will also finish up a few projects I never completed which will close the door on this part of my woodworking experience. Having made 10 guitars and mandolins over a few years was both eye-opening and very rewarding. Nothing will take your woodworking to a level of precision like the technical demands of building a guitar. My archtop guitar remains the project I am most proud of to date - I will have to work pretty hard to surpass that accomplishment. BTW - I have kept all my premium wood sets, so if you are looking to build a guitar or two, come see me...

The off-time during Christmas was consumed with some painting around the house, and the pumpkin orange in the hallway has been muted to a cream off-white. Your retinas will thank you.

Update on Christmas build...

|

| How do you do siding in bird-scale? Tilted dado blade and voila! |

|

| The finished birdhouse "in the white" |

|

| The finished bird condo, after receiving the full Kim treatment - awesome! |

Shop Clean-up and some turning:

|

| We needed some cutting boards she said... |

|

| Is this enough already? |

As you see I have been working through lots of pieces of material, although it does not appear to have made much of a dent.

I will have to re-dedicate myself in the coming months to this purpose - fail, I shall not...

|

| This piece of punky apple came from Yarmouth in 1999! |

|

| This round piece of Maple had 1996 written on the edge - c'mon man! |

Another project from the material stores...

I have also been busy on a piece of furniture - this time for us. We wanted a sideboard for the dining area to replace a shelf that mysteriously disappeared after my youngest son bought his new house. I am not saying anything in particular here - the timing definitely was a coincidence.

|

| The money shot - cherry and ash sideboard in its new home. Size: 48" w x 16" d x 30" h |

Those not interested in woodworking techniques and the man glitter that we all know sawdust is - click away now.

|

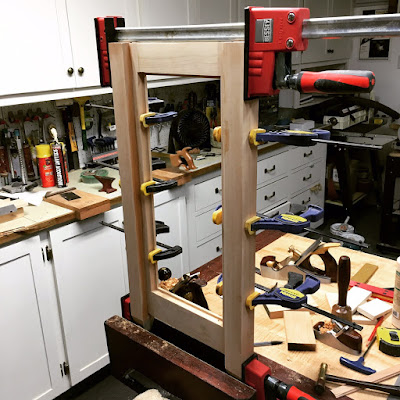

| The end frames are glued up and make extensive use of dominoes for easy joinery. |

|

| The ash end panel looks like separate boards, but I chamfered the edges before gluing them up. Expansion s[ace was left on the edges behind the strips holding them in place. |

|

| The back is designed with individual cherry slats shiplapped and screwed to the back. I wanted a finished look in case this became a free-standing piece. And yes the screws are clocked!! |

|

| This unit has a couple of drawers and of course I am going to dovetail them. I don't dovetail all the time - but when I do, I use the David Barron jig! :-) |

|

| All glued up with a coat of oil to seal. |

|

| Another shot with the drawer open and shelf installed. We chose the clean drawer front look without hardware. drawers have a centre glide hidden underneath. |